THE CANARIAN INSTITUTE OF TECHNOLOGY (ITC) AIMS AT PROMOTING THE INDUSTRIAL DEVELOPMENT OF THE CANARY ISLANDS THROUGH R+D+I ACTIVITIES AND PROVIDES TECHNICAL SERVICES TO SMALL AND MEDIUM-SIZED ENTERPRISES IN THE FOLLOWING AREAS: RENEWABLE ENERGY, DESALINATION AND WATER TREATMENT, ENVIRONMENTAL SCIENCES, MEDICAL ENGINEERING AND BIOTECHNOLOGY.

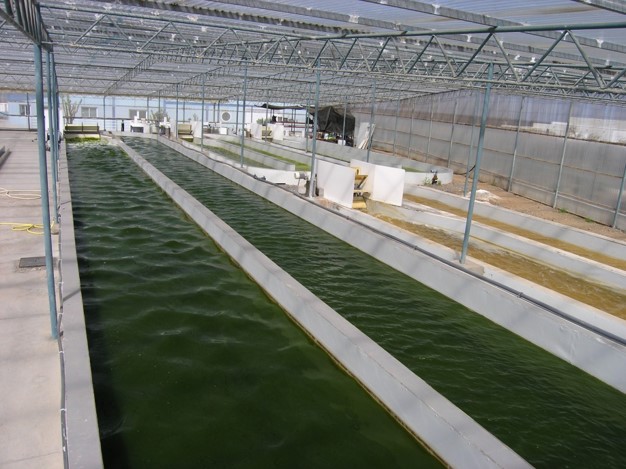

In ITC biotechnology department, experiments are carried out to test the biotechnological aptitude of native microalgal strains at a semi-industrial scale. The department also provides companies with scientific-technological support (infrastructures, equipment, consulting), helping them to develop systems for producing and processing microalgae in the ITC facilities.

THE ITC BIOTECHNOLOGY DEPARTMENT DEALS WITH TWO MAIN ACTIVITIES:

- scientific-technological support (infrastructures, facilities, equipment, advice) for the production and industrial processing of microalgae → companies (incubated/hosted)

- applied research on new technologies for microalgae cultivation and processing on a pilot and industrial scale (demonstration projects) → technology transfer

SCIENTIFIC-TECHNOLOGICAL SUPPORT (INFRASTRUCTURES, FACILITIES, EQUIPMENT, ADVICE…) FOR THE PRODUCTION AND INDUSTRIAL PROCESSING OF MICROALGAE → COMPANIES (INCUBATED/HOSTED)

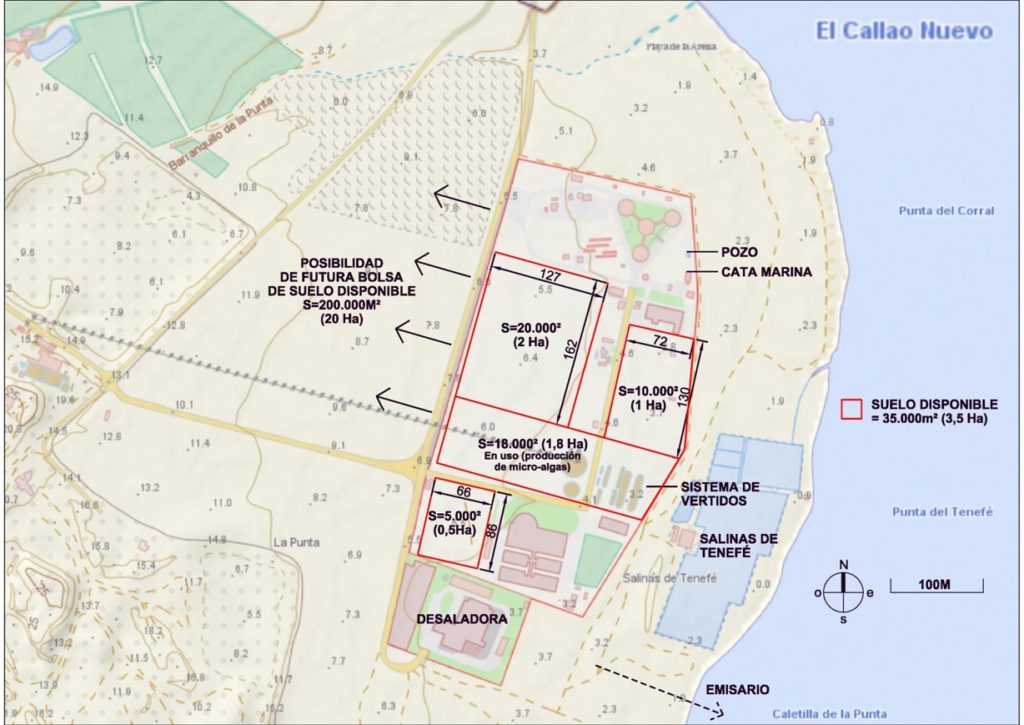

Acquisition, adaptation and development of infrastructures, facilities and basic scientific-technological equipment for the industrial development of microalgae production on the island of Gran Canaria (Pozo Izquierdo, ITC lands and annexes) → Support and logistical technical support / 1st Area Technological-Industrial Development

- Supply of all types of water: seawater, hypersaline, brine, desalinated water (not Chlorine-treated).

- Experimental development of an integral management system for the treatment of the waste generated by the algae production activity.

- Algae processing plant with sanitary registries, equipped with centrifuges, spray dryers, freeze dryers, etc.

- Electrical supply of the area by renewable energy.

- Systems for the supply of combustion gases from nearby industrial processes (cleaning, purification, compression and channeling)

- Member of the Platform of Excellence in Blue Biotechnology (land farms: algae, crustaceans, mollusks and fish)

→ POLO I (Area of scientific research / Taliarte): Multidisciplinary scientific and technological counseling, analytical services, support to entrepreneurs, specialized education, recruitment of researchers, etc.

→ POLO II (Experimentation and Incubation Area / Arinaga): 7-12 hectares

→ POLO III (Area of Technological-Industrial Development / Pozo Izquierdo): 3.5 hectares within the ITC facilities available for the development of industrial projects for the production of microalgae (+ 20 hectares of potentially compatible land all around)

APPLIED RESEARCH ON NEW TECHNOLOGIES FOR MICROALGAE CULTIVATION AND PROCESSING ON A PILOT AND INDUSTRIAL SCALE (DEMONSTRATION PROJECTS) → TECHNOLOGY TRANSFER

- Transfer of technologies and methods to cultivate and process the following microalgal species:

- Dunaliella salina

- Tetraselmis striata

- Chlorella sp.

- Arthrospira sp.

- Nannochloropsis sp.

- Navicula salinicola

- Salt + Dunaliella salina

- Development of new cultivation and processing technologies, biotechnological processes (bioremediation, CO2 sequestration etc.) and product applications (human and animal food, cosmetics, nutraceuticals, fertilizers…) → technology transfer to private companies.

- Staff (Production Manager, Laboratory Manager, Processing Manager, Laboratory Technicians, Aquaculture Technicians, Maintenance Operators, Project Researchers/Technicians…)

- Production plant: 1,500 m2 (greenhouse: raceways and photobioreactors) + 1,800 m2 (future ITC extension)

- Processing plant: centrifuges, atomizers, lyophilizers, etc.

PREVIOUS PROJECTS

| BANGEN |

|

Creation of a marine gene bank of Macaronesia. |

| FAM |

|

Design and development of new food products from microalgae. |

| TRES |

|

Transition to a sustainable energetic model for the Macaronesia (microalgal biomass as biofuel) |

| LACTOALGA | Use of whey for heterotrophic cultivation of microalgae | |

| VENTURI |

|

Use of venturi diffusers in desalination plant brine discharges to reduce environmental impact. |

| INMOSEAWEED | Microalgae in animal nutrition to enhance immune system. | |

| PSE-Microalgas |

|

Industrial uses of microalgal biomass. |

| OMARAT |

|

Extremophiles microalgae from Morocco. |

| ALGALIMENTO |

|

Development of a production chain of marine and hypersaline microalgae biomass toward food market |

| DOWNSTREAM |

|

Pre-industrial scale optimization of microalgae production and development of cost-effective drying methods. |

| TECHMARAT |

|

Development of a marine algae biotechnology for the Atlantic region (Canarias-Morocco) |

| ALGABIOMAC | Development of biotechnology industries from exploiting macro and micro marine algae of the Macaronesian regions (and neighboring third country) | |

| APRENMAC | Use of endogenous resources for sustainable development activity sectors and high added value: biotechnology, water and energy | |

| BIOVAL | Recovery, control and management of marine resources from Macaronesia. | |

| MACBIOBLUE | Demo project for helping companies to develop new products and processes in Macaronesia’s blue technology scope | |

| REBECA | Excellence blue technology network (microalgae) for the Macaronesia region | |

| MIMAR | Tracking, control and mitigation of marine organism spread associated to human and climate change disturbance in Macaronesia region | |

| ISLANDAP | R+D+i towards aquaponic development in the up islands and the circular economy |